One of my first assumptions was that it would be easier to design and build a casemate vs. turreted tank. So far, my experience in the project has supported this assumption. I didn't automatically eliminate all turreted designs, they were just not as heavily weighted.

Curves were also a big consideration. While curves on a woman are desirable, on a scale tank not so much so. On a tank, curves are a result of the armor being cast into shape. As the WWII progressed, tanks became more angular; think early Sherman compared to a Panther. Tanks made from sheets of armor, cut and welded, are easier, faster and cheaper to build then those were the major pieces are cast. Many tanks were a combination of both. When building on this scale, accurate curves usually means fabricating with fiberglass. That would mean an additional skill set to be learned. Not a deal breaker, but certainly a major detractor.

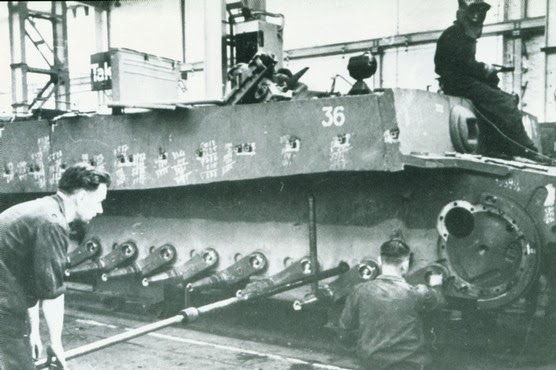

The last major consideration was the tanks road wheels and suspension. Some tanks have incredibly complex suspensions, such as the Matilda. Some are very simple like the Tiger. The number and size of road wheels is the other part of this. Smaller wheels are easier to fabricate and fewer wheels are more advantageous for budgetary concerns. An extreme would be a Tiger I with 48 large diameter road wheels compared to a M3A1 with 8 medium to small sized road wheels.

|

Matilda Suspension |

|

Tiger Suspension |

|

M3A1 Stuart road wheels- 4 per side |

|

Tiger I road wheels- 24 per side |

So how does the Hetzer stack up? The Hetzer is a German late war tank destroyer, i.e. a casement design. The only rounded/curved surfaces is the gun mantle. Since the mantle will be one of the last things done; I still have time before I need to tackle that particular learning curve. It only has eight road wheels, though they are of large diameter. It's suspension is fairly straight forward (leaf springs) and easy to replicate. The Hetzer is very squat (intentionally) in stature. While a low profile makes for a smaller target in real life; it also means I had to go slightly larger in scale then originally planned to allow for enough inside height for me to comfortably fit in the thing.

Coming up next, I start tackling the CAD (computer aided drafting) side of the project...

Coming up next, I start tackling the CAD (computer aided drafting) side of the project...

No comments:

Post a Comment